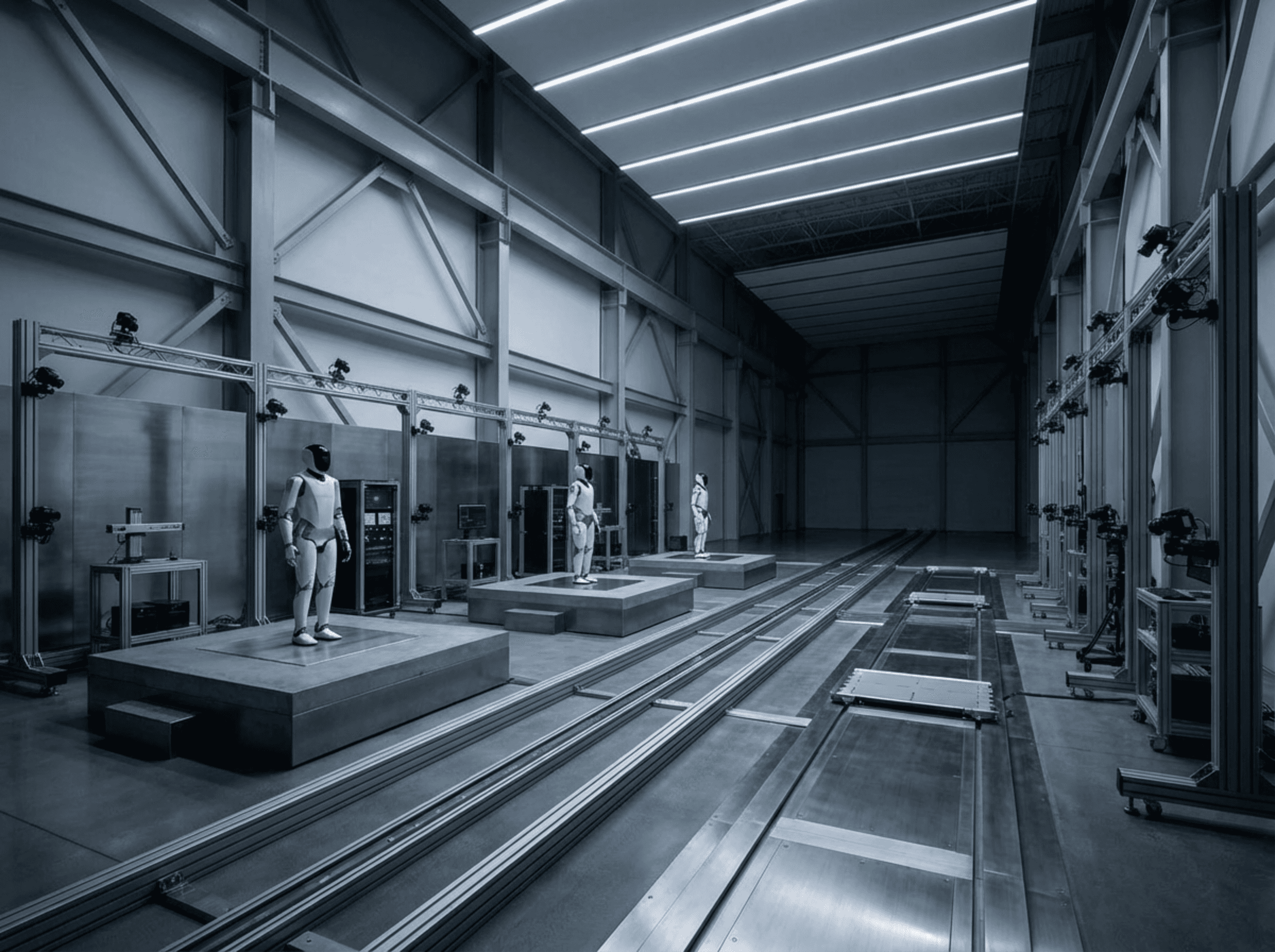

A controlled environment where motion becomes measurable

AEVA’s precision motion lab is one of the company’s most advanced engineering spaces — a dedicated environment where movement is stripped of ambiguity and evaluated with mechanical clarity. The lab was built to support AEVA’s core philosophy: autonomy should behave like engineered hardware, not like a loosely constrained software model.

The hall itself is long, quiet and designed with deliberate emptiness. Most of the floor area is reserved for calibration lanes, gait platforms and adjustable terrain rigs. Each element exists to introduce a specific variable and verify that the AEVA-UNIT 079-E7 reacts predictably.

Measuring stability at every millimeter

At the center of the lab is the linear motion rail system, a precisely machined track that allows engineers to study gait and posture at micro-resolution. Cameras, motion sensors and foot-pressure arrays record how each unit adjusts weight, angle and force as it moves.

One section of the lab replicates uneven surfaces: slight ramps, sharp step-ups, and textured floor plates. These are not dramatic obstacles. They are subtle, engineered imperfections designed to validate how well AEVA maintains controlled zero-drift locomotion in realistic environments.

Another zone handles slow-motion capture workflows. Here, AEVA units perform routine tasks under high-speed imaging so engineers can identify micro-instabilities invisible at normal speed. This is where the team refines everything from ankle torque response to upper-limb micro-corrections.

Industrial acoustics and low-noise systems

Because AEVA is designed for homes, offices and night-shift environments, the lab also houses acoustic testing chambers. These measure motor signatures, actuator vibrations and harmonic resonance across different movement patterns.

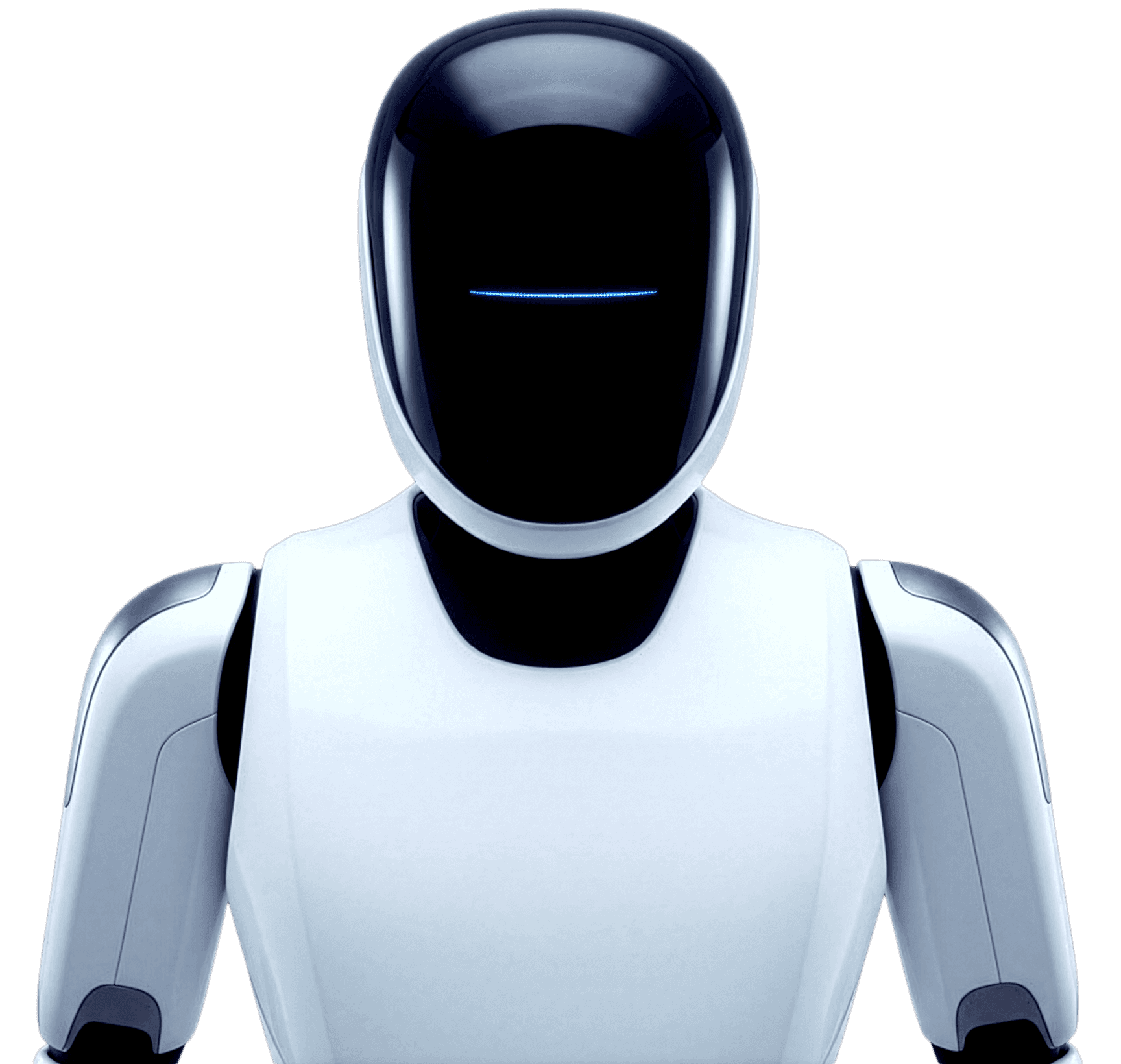

The goal is not silence for its own sake. It is predictable, non-intrusive movement — motion that blends into human environments without demanding attention.

A place where precision defines the product

The precision motion lab represents AEVA’s commitment to the heavy, unglamorous engineering required for safe autonomy. Every improvement made here feeds directly into real-world deployments, whether in a Shinjuku kitchen, a multi-level residence or a high-heat inspection site.

It is a space built around the idea that if autonomy is going to work in the world, it must be measured, validated and refined with the same discipline as aerospace hardware — not treated as an improvisational experiment.