Case Study

Sushi Restaurant Deployment

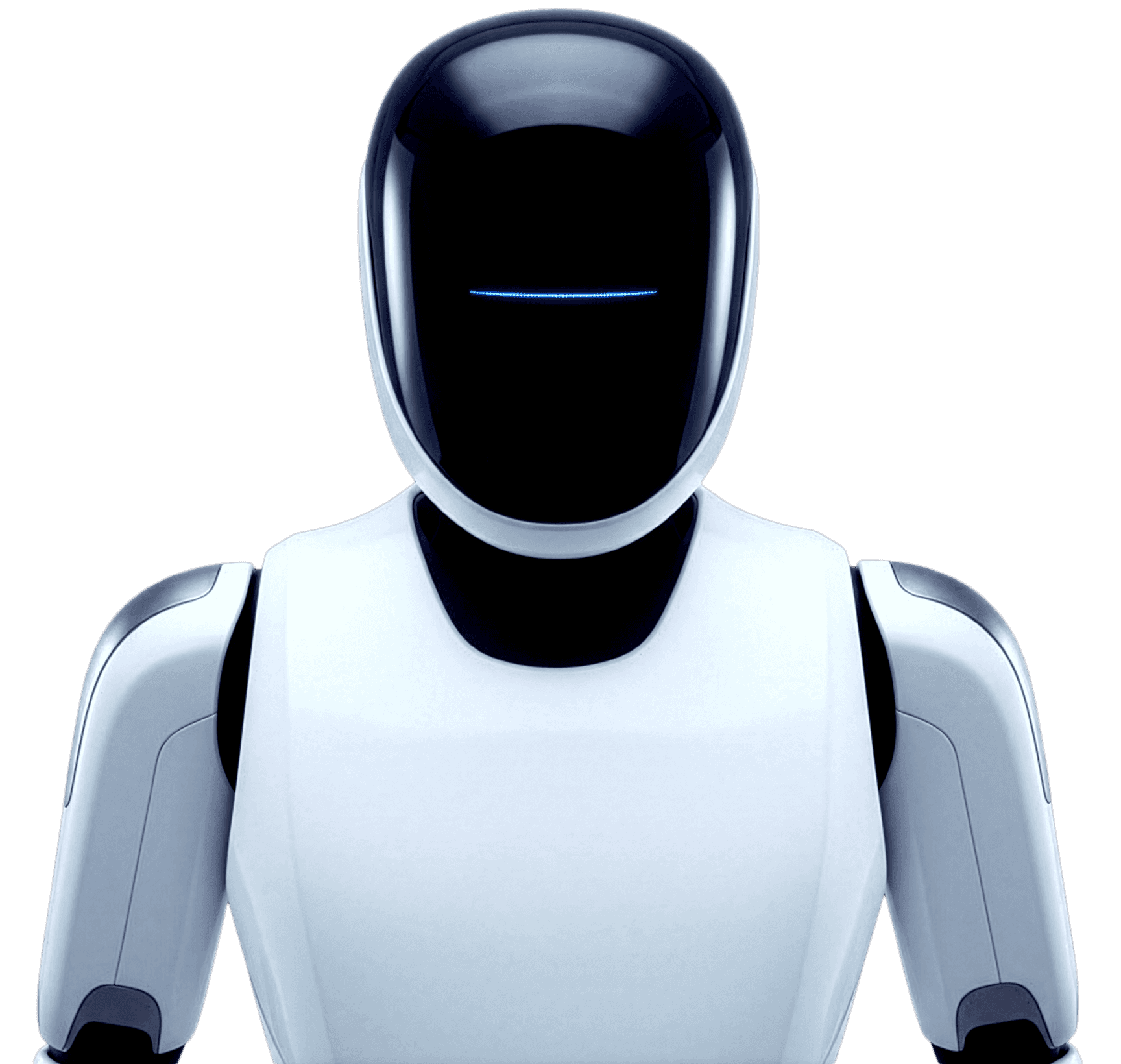

Three AEVA units supporting a high-volume sushi kitchen during peak hours, managing precision tasks with consistent accuracy.

Operational Deployment in High-Volume Environment

During the peak dinner rush in a Shinjuku sushi restaurant, three AEVA units were deployed across cutting, frying, and plating stations. The environment demanded precision under heat, steam, and rapid order flow. AEVA units immediately integrated into the kitchen’s rhythm, handling repetitive and time-sensitive tasks with consistent output.

Stable Performance Under Pressure

Across a 4-hour and 38-minute service window, all AEVA units operated without performance drift or interruption. They managed knife work, high-temperature woks, and delicate plating sequences while navigating tight spaces alongside human staff. Task accuracy remained at 99.4%, with zero operator interventions required.

Improved Throughput and Workflow Efficiency

The restaurant reported smoother coordination between stations, increased service speed, and a reduction in human error during the highest-demand periods. AEVA’s stable and fatigue-free performance allowed the chefs to focus on creative work and quality control. The deployment confirmed AEVA’s capability to enhance output and maintain consistent standards in fast-paced hospitality environments.

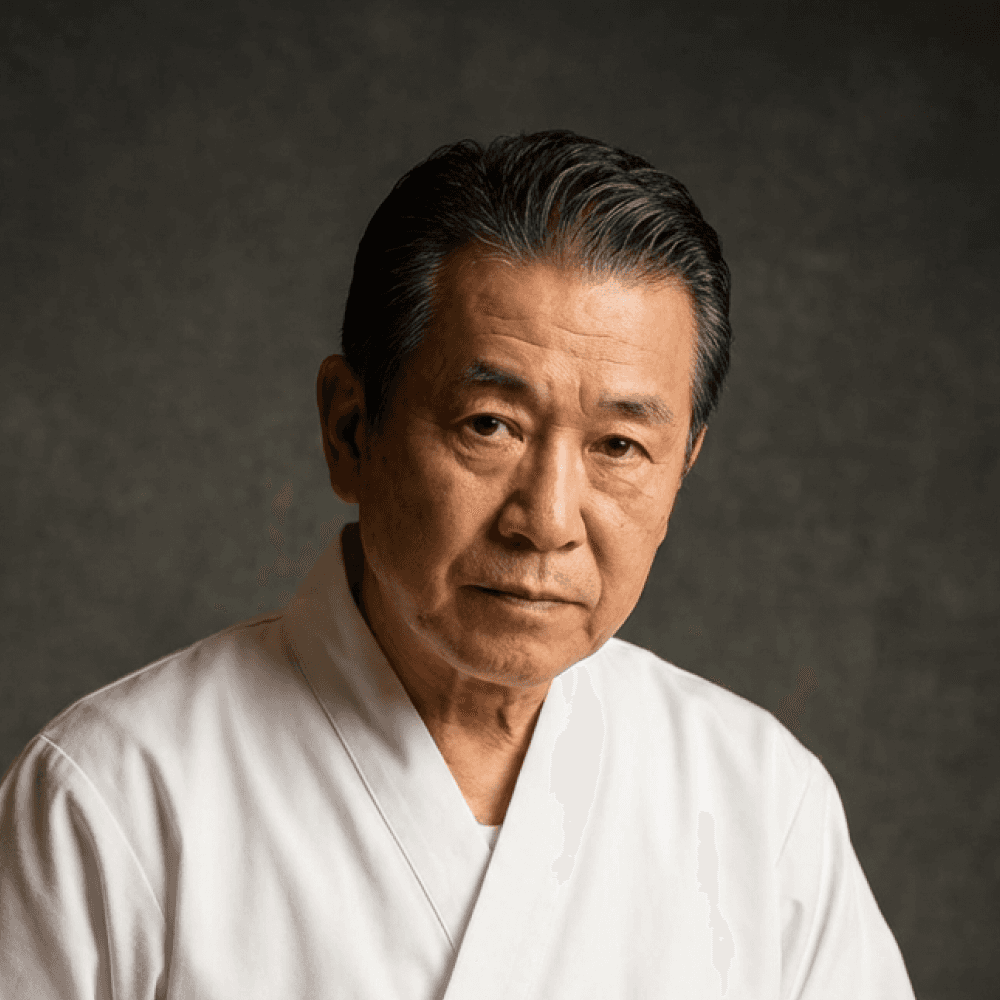

AEVA holds an accuracy level our staff can’t maintain during heavy rush. Zero mistakes, zero delays.

Hiro Tanaka

Head Chef